|

Custom kitchen cabinets require a considerable budget. One way to keep renovation on budget is to use stocking kitchen cabinets. Stocking RTA kitchen cabinets are a more affordable cabinet option. They're usually in stock and ready to take home from cabinet specialty or home improvement stores; this makes them popular among many home renovators. Stocking kitchen cabinets are sold either fully assembled or ready to assemble, so that DIYers are able to personally install them and save labor costs. Stocking Cabinets are pre-manufactured in industry standard three-inch width increments and placed in inventory by style and color. Size modifications are available and separate fillers will be required to fit kitchen cabinets to existing room conditions. Stocking kitchen cabinets have a rich cabinet configurations available to meet various design objectives. With stock cabinet finishes, what you see is what you get. Each door design is only available in the finish shown. Toner coats, equalizers, and stains are sprayed on in advanced computerized production lines. Finish inspection takes place prior to packaging. Quality of Stocking cabinets depends on cabinet manufacturer Cabinet factories are not made the same. Cabinetry Factory is the only kitchen cabinet factory in Veitnam that have both top quality and strong open production capacity. And Cabinetry Factory genuinely produce whole cabinets in Vietnam. Kitchen Cabinet doors and components are pre-made, mass produced, and imported. The components are mass assembled in domestic factories where they are pulled from inventory and put together on assembly lines. When a kitchen is ordered, the prefinished cabinets are quickly pulled from inventory and shipped by the truckload. Stock price and delivery expectations. Bypassing the manufacturing process allows stock cabinets to be delivered in as few as two weeks. Understanding the difference in cabinet constructionWhat exactly does it mean for a framed cabinet or frameless cabinet? And what distinguishes one from the other? Exploring the unique differences between the two helps you determine which one is best suited to the needs of your kitchen or bathroom. What are framed cabinets?Framed kitchen cabinets have been a staple of American cabinetry for years, more traditional and they continue to be popular even today. That’s why they’re sometimes called “American style.” As the name suggests, framed kitchen cabinets have a face frame that covers the front of the cabinet box. The 1-½ inch face frame is comprised of rails and stiles and resembles a flat picture frame. The structure with a front face frame makes the framed kitchen cabinet more rigid and sturdy. The face frame also helps keep the cabinet square. The door is secured to the frame, adding dimension to the door front. Framed cabinets are appealing to many people because of their variety. We can mount the doors inside of the frame for an inset style, or expose part of the frame by mounting the doors to the front of the frame for a partial overlay or full overlay. Partial overlay is associated with less expensive cabinets because less wood is required to build doors and drawers when compared to full overlay where the doors and drawers cover the face frame almost completely.Framed kitchen cabinets with full overlay doors create an appearance that is very similar to frameless cabinetry. What are frameless cabinets?Frameless cabinets came to the US from Europe; they’re sometimes called European style. Frameless cabinets are frequently referred to as “full access” because no cabinet space is taken up by a face frame and they offer ease access to the interior of the cabinet. Only full overlay doors are used with frameless cabinets and the door are attached directly to the sides of the cabinet box. A veneered front edge is applied that hides the rough or raw plywood or furniture board edges.

Considered the modern alternative to the more traditional choice of framed cabinets, frameless cabinets offer a very sleek and streamlined appearance. Also, interior storage space is slightly larger within frameless cabinetry. Each kitchen cabinet construction method has its advantages and disadvantages; no one style is “the best.” Each has its merits. There are literally hundreds of cabinet producers and probably thousands when you include all the local and small-business cabinet makers. While there is skill and craftsmanship necessary to produce quality results, producing quality doesn't necessarily require highly complex machinery or factory conditions. In other words, you may find a talented carpenter or local cabinetmaker with the ability to produce fine cabinetry.

Given the number of cabinet producers, you're probably asking what the differences are, if any, among them all. In reality, the differences are really found in the same general categories that make them similar. It's back to the car analogy again: the auto manufacturers all make vehicles that do the same job; they're just variations on a theme. How They're Similar

How They're Different

So what's the bottom line when it comes down to sorting through all the various cabinet makers? There's no right or wrong way to narrow down to a short list of candidates but here are some suggestions:

So who are the best kitchen cabinet manufacturers? While it's a legitimate question, the answer isn't as definitive as you might think. And here's why: There are makers of cabinets almost too numerous to catalog, let alone do independent tests on to determine who's best. I'm sure Consumer Reports has their short list of brands that they rate as good/better/best. But how many do they test relative to what's available in the marketplace? Second, the determination of "best" is somewhat subjective. Sure, there are definite indicators of good quality and poor quality but there isn't one gold standard. One person may think that anything other than plywood construction is "poor" quality. However cabinets made with medium density fiberboard may be just as durable and last just as long. Let common sense prevail here. "Better" products are those made with stronger construction techniques and more durable finishes. But there aren't only 5 or 10 of these manufacturers out there. To some extent cabinets are a commodity. There are probably hundreds of producers that fall into the "best" category if you look across the spectrum of national and local manufacturers. Your most effective way to find the best brands are to look at what is available to you locally (both from a 'national' brand perspective as well as local producers) and see how they compare. Then, determine how they match up with your budget. What you should be shooting for is a kitchen cabinet manufacturer that can give you the most of what you're looking for (quality -- as you judge it, options, quantity, etc.) for what you're willing to pay. In my opinion, that's your "best" kitchen cabinet maker. Because at the end of the day, even if someone was able to say that Brands A, B & C are the best brands, they may not be the best fit for your budget. You need to take some responsibility for understanding what makes cabinets good/better/best and make an educated buying decision. I think that's a more rational approach than simply relying on an arbitrary list of "great" kitchen cabinet producers. Kitchen cabinet quality is essentially a function of the materials, construction methods, finish and craftsmanship used in the cabinet-making process. There's variability in all of these ingredients which results in a corresponding range of cabinet quality.

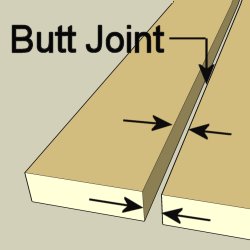

What Exactly Is 'Quality'? Before we get too far into the subject of cabinet quality, it will probably help to get a firmer understanding of just what that term means. "Quality" is something that's hard to pin down because at its root, it's subjective. One person's view of good quality may be another's interpretation of just "fair" or even "poor" quality. However, everyone of us still knows 'good quality', (whatever it means to us), when we see it. You've no doubt looked at a product of some sort that you felt either demonstrated good quality or it didn't. Being specific about what it was that brought you to that conclusion is a harder task however. In the end it was probably because it either "looked" a certain way (sturdy, good attention to detail, no flaws) or if you actually bought and used the product, it met or exceeded your expectations in some way. Maybe it lasted longer than you expected or performed it's job with no hiccups. Kitchen cabinet quality is no different. You'll encounter a range of materials and methods of assembly and in the end, you'll have to judge whether the product meets your quality standards. What we hope to point out here are the important characteristics that define kitchen cabinet quality and the variation within the quality spectrum. What To Look For In Kitchen Cabinet Quality To start with you might be asking "Aren't there any standards that define good quality?" The answer is yes, there are some standards established within the industry but they're not "rules" that must be complied with like airlines that must conform to FAA regulations. The KCMA, a cabinet industry trade organization, has established criteria that must be met in order to meet their certification requirements. However KCMA certification is elective and the lack of it doesn't imply poorer quality. At a minimum it gives you some baseline for the level of quality and durability a particular certified cabinet line has achieved or that other cabinet products can be compared to. Beyond that there's also some basic common-sense standards associated with cabinet quality that will help you discern between better and poorer kitchen cabinet quality. This gets back to the point about 'knowing quality when you see it'. For example, thicker materials will be sturdier than thinner materials or construction techniques like dovetail joints are more durable than glued butt joints. But despite those characteristics that are plain and obvious, there are others that you might not be aware of like cabinet box reinforcement variations and drawer slide ratings. So what should you be looking for to discern good cabinet quality? Focus on what the the basic components like the cabinet box, drawers and shelves are made from and how they're assembled. Also pay attention to the finish, how it's applied and the coatings that are used. So read on! Hopefully in the end you'll have a good understanding of the range of kitchen cabinet quality and which attributes are better than others. Cabinet Box Material And Construction In their most basic form cabinets are nothing more than boxes that are made in varying sizes and of different materials. However that's where the similarities end. How these boxes are held together and the materials they're made from vary among manufacturers and even among product lines at any given manufacturer. Materials When it comes down to the materials that make up the box, there's debate over which is best because it depends what "best" means to the individual. Consider the options: solid wood (for face frames), plywood, particle board and medium density fiberboard (MDF). Some cabinets also use a material called 'hardboard' for floors and cabinet back panels. The material cabinets are made from is important because it plays a key role in the durability, longevity and quality of service the cabinets provide. Material properties such as rigidity, screw holding power and susceptibility to moisture and humidity will vary based on the material used in the cabinet's construction.

Less preferable are smaller, thinner reinforcing pieces made from particle board and stapled or just glued in place. Some cabinet manufacturers make corner gussets from plastic. Thick, substantial plastic that is securely fastened to the side panels is preferable over flimsy plastic parts. Here again, your eye can usually spot the superior products over the inferior ones (keep asking yourself, "does it look/feel solid or flimsy?"). Larger corner gussets are more effective than smaller ones because they 'reach out' and support more of the cabinet walls that they're attached to. This does a more effective job in keeping the panels square and rigid, particularly as the size of the cabinet box gets bigger. Box Construction In a broad sense, better, more durable cabinet boxes possess:

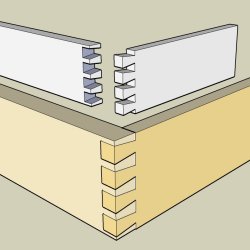

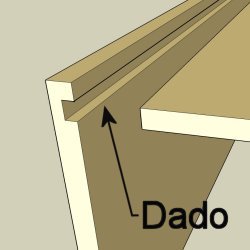

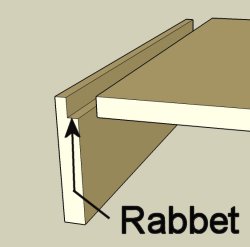

Your cabinets end up holding a substantial amount of weight from stacked dishes to canned goods. The shelves that directly support that weight rely on the brackets attached to the sides of the cabinet box. Thinner panels might bow or twist, particularly if they're not reinforced in some way. The thickness of typical cabinet box side panels varies by manufacturer and product line. Thicknesses you'll see are 3/8, 1/2, 5/8 or 3/4 inch thick. Back panels range from 1/8 to 1/4 inch thick. Thicker panels provide more rigidity. For comparison purposes take a look at the relative thicknesses of these typical materials used in cabinet construction. As you can see there's a significant variation among them. The 1/8" hardboard on the left is used in some cabinets for the back panel. Typical cabinet box side panels are made from 1/2" stock with available upgrades to thicker material. Drawer And Drawer Slide Construction Cabinet drawers work hard because they hold a lot of the everyday items we use such as cooking and eating utensils. Because they're opened and closed frequently they take more of a beating than some of the other cabinet components. Better drawer construction means more durable and longer lasting drawers. Cabinet drawers aren't complicated and there's just a few points to focus on. Pay attention to how the drawer box is constructed and the kind of slides they're mounted on. Drawer Box Construction Joint Construction - methods of construction involve dovetailed joints, doweled or rabbet joints, glue and staples or a combination of these. Dovetailed joints are the most durable (provided they're tight with no gaps or looseness). Doweled and rabbet joints are next down the line with the glued/stapled joints at the lowest end of the quality spectrum. Box Material - drawer box materials (for wood-based cabinets) include solid wood, MDF, plywood or particle board or a combination of these materials. This is one location where solid wood is still fairly common in cabinet construction. Solid wood combined with good joinery results in the strongest drawer box. This is due to the inherent superior qualities of solid wood over particle board such as screw holding capability and resistance to moisture. (Despite your best efforts, someday you'll end up spilling some sort of liquid into an open drawer.) Bottom Thickness, Material and Retention - thicker bottom panels are better than thinner ones because the bottom panel supports the weight of the drawer contents. You'll see thicknesses ranging from 1/8 inch to 1/2 inch (keep in mind that 1/2 inch is 4-times thicker than 1/8 inch). Drawer bottoms that are dadoed into the 4 sides of the cabinet box represent good construction because it 'captures' the drawer bottom. Much less durable methods involve just stapling and/or gluing the bottom panel to the drawer box. Drawer Slides Slide Material - slides and their various parts are made from metal, plastic, nylon or a combination of these materials. Look at the rolling elements (the rollers or parts that actually allow the slide to move back and forth) and how the slide is attached to the back of the cabinet. Stronger more durable slides will use roller mechanisms that have steel ball bearings and have metal attachment fittings where they fasten to the cabinet box. Plastic and nylon attachments and rollers will be less durable than metal. Load Rating - the load rating defines the amount of weight the drawer slides can support, which includes the weight of the drawer itself. Typical cabinet drawer slides are rated at 75 to 100 lbs. capacity. The higher capacity slides will handle more weight. Wider drawers or large pull-outs like recycling centers may require slides with a higher load rating. Mounting Location - drawer slides are mounted on the sides (sidemount) or under the drawer (undermount). Sidemount slides result in a narrower drawer and less interior space for a given cabinet width compared to undermount slides because of the room the slides occupy on the side of the drawer. While this isn't necessarily a durability issue as it relates to quality, having more drawer space by using undermount slides is usually preferable over a smaller drawer. Higher-quality cabinet lines use undermount drawer slides over side-mount slides. Extension and Adjustability and Special Features - slides are classified by how far they allow the drawer to extend. They can be 3/4 extension, full extension and over-travel. Full extension and over-travel slides allow the drawer to be pulled all the way out (or past all the way for over-travel drawers) which affords access to the entire drawer all the way to the back. With 3/4 or "normal" extension a portion of the drawer remains inside the cabinet. You'll have to bend over to see or fish out the contents in the back. The lower the drawer is on the cabinet, the more inconvenient this gets. Adjustable drawer slides are another good feature to have. They allow the drawers to be realigned in height and side-to-side as needed should they go out of alignment over time due to wear or shifting. Better quality drawer slides also include added features such as soft-close action which causes the drawer to close itself once it's pushed past a certain point. Shelf Thickness, Retention And Adjustability Thickness And Material Despite their simplicity the shelves are another key component in your cabinets because they carry the major part of the load within the cabinet. Thickness and material choice are the important factors since they govern both the rigidity and strength of shelf. Plywood and solid wood are the best choices for shelf material as they provide better rigidity than MDF or particle board for a given thickness and shelf span. Obviously the thicker the shelf, the more rigid and less prone to sagging it will be. Also, shelves that have a reinforcing strip made from solid wood or plywood attached to the front edge or underneath are more rigid than shelves without this feature. How a load is place on a shelf will determine it's strength and resistance to sagging. In the case of kitchen cabinets the load is the 'stuff' you store on the shelves like dishes and food items. Don't underestimate the weight of some of these items - lift your entire stack of dinner plates sometime to get a feel for what your cabinet shelves experience. The weight of a stack of plates, bowls or canned goods can add up pretty quickly and the closer to the center of the shelf you store them the more strength that shelf will need. In general, shelf thicknesses range from 1/2 to 5/8 to 3/4 inch. The thicker 3/4 inch shelves are the preferable option based on their increased rigidity over thinner shelves. If you work with a custom manufacturer you should be able to specify whatever thickness you want. They should also be able to guide you on the best thickness for a given span length. Although most cabinet shelves top out at 3/4 inch thick, don't hesitate to go thicker on a custom cabinet if you need the extra support. Retention And Adjustability Adjustable shelves are obviously more versatile than fixed shelves. Good quality cabinets will have adjustable shelves or at least more of them than fixed shelves. For adjustable shelves make sure you're satisfied with the clips that hold up the shelf. Metal clips are sturdier than plastic clips. Shelves need to be strong but so does the hardware that holds them up. Look for metal supports rather than plastic. Also, look for supports that appear "right-sized" for the shelf span. There's no hard and fast rule here but brackets with a longer "reach" under the shelf are better than small ones, provided they're made from a solid material appropriate for their size. Note the small size of these shelf-holding pins in the picture on the right. Wider shelves and heavier loads might tax brackets of this size. The way the brackets are held into the cabinet sides is also important. Long shelves that support more weight put a heavier load on the brackets. Brackets that are just pins inserted into a hole in the cabinet sides aren't as durable as shelf standards. Shelf standards are metal channels that are attached to the inside walls of the cabinet box that accept metal clips to support the shelves. In some designs they're recessed inside a dado cut into the cabinet wall. They may be a bit more obtrusive looking but they offer a sturdier alternative than small pins pressed into a hole in the side panels of the cabinet. Cabinet Finish A good quality finish not only makes your wood cabinets look nice but it also goes a long way in protecting your investment. Why is that? Well, consider the environment your cabinets operate in. Have you ever had boiling pasta or lobster on the stove? Or maybe you have a stove-top grill. There's lots of moisture, greases, and temperature changes that occur in a hard-working kitchen. That's not to mention the many times the drawers and cabinet doors are opened and closed or leaned on with dirty or greasy hands. Then there's the occasional spill of vinegar or ketchup down the front of the cabinet door. A good quality cabinet finish will go a long way in making sure your cabinets aren't phased by this onslaught. Elements Of A Quality Finish Look for the following components in a quality cabinet finish: Catalyzed varnish or lacquer - a catalyzed varnish or lacquer has properties that enhance the durability of the coating beyond non-catalyzed varnish/lacquer. These qualities allow it to weather the harsher environment that kitchen cabinets are subjected to. Non-catalyzed coatings aren't as durable and will be more susceptible to damage. Note: you may see references to 'conversion' varnish or catalyzed conversion varnish. This is also a durable coating material. High-solids content - a finish, usually a varnish, with a high solids content provides more protection for the underlying wood and stain. "High solids" means that there's actually more solid 'particles' within the coating system. Those solids help to build up the coating thickness which ultimately provides a durable shield over the material underneath. UV protection - finishes and coatings that include constituents that resist fading from ultraviolet light are desirable over those that don't. Cabinets in a sunny kitchen will be exposed to fading from the UV light present in the sunlight. Regardless of who you buy your cabinets from make sure you understand what they're finishing process entails. Good wood finishing, particularly when using coatings like a catalyzed varnish, requires knowledge, tools and the right conditions to achieve a quality result. Think that all kitchen drawers are made alike? Well think again! Dovetail drawers offer many benefits that regular drawers just can’t match, continue reading to find out just what these benefits are!

Dovetail drawers require a different type of construction than standard kitchen cabinet drawers, and are usually regarded as a higher quality drawer option for homeowners. The difference between dovetail drawers and other, more traditionally constructed drawers, lies within the type of joint used in dovetail drawers. The type of joint constructed for dovetail drawers is known as a ‘locking joint’. The dovetail ‘locking joint’ is constructed from wedge-shaped channels cut into the wood, that interlock with one another from either side of the drawer, creating a box. The wedge-shaped pieces are called ‘tails’ and ‘pins’, and provide a very strong joint that is quite resistant to force once the two sides are assembled. The dovetail joint is so strong that oftentimes when a drawer breaks, it is not at the point of the joint. Not only is the ‘locking joint’ itself strong, but the joint’s surface is large enough to offer an unusually large area for gluing. Glue is stronger than wood, and therefore the more space that is available for gluing allows for an even stronger drawer box. Due to the construction of the joint, dovetail drawers also offer the largest storage space. British dovetail drawers, which are the type we have been talking about, allow for the largest possible drawer, regardless of the type of furniture. French dovetail drawers are a proper choice for specialty furniture, like pieces with curved fronts. Joints on French dovetail drawers are constructed slightly different, with the drawer side sliding upward into a long groove at the drawer’s front. The advantages of dovetail drawers are in the construction of their joints. They offer a stronger drawer, with a larger holding capacity. While these drawers are associated with a higher quality drawer, this is not always the case. There are many options for drawer construction, and picking the correct drawers for your kitchen cabinets should include strength and storage. Nobody likes the sound of banging cabinet doors and drawers. And while you can’t do anything about the nuisance caused by these during the rush hour at lunchtime in your local diner, there is a way you can rule this out at home.

You may have heard the terms “self-closing” and “soft-closing” before, but they are not the same. Self-closing systems operate on a spring-like mechanism that pulls in doors and drawers as soon as they are opened, which isn’t always silent. Soft-closing systems, on the other hand, stop the drawer or door when pushed to a certain point, and then activate hydraulics to pull them in the rest of the way, thus shutting them without sound. According to Cabinetry Factory, self-close drawers have been in the industry for many years, but soft-close pieces are only just beginning to get popular. It seems Europe is the hotbed for testing out these new technologies before the rest of the world picks them up. Drawer Slides Drawers in the 50’s and 60’s contained noisy metal slides on their sides, known as Grant slides. And then inexpensive epoxy-coated slides with ball bearings were created in the 80’s. These revolutionized the mechanism of drawers and quickly became the mainstay of the furniture industry. When the drawer is a side-mount type, 1/2 inch clearance is required on either side. This is to accommodate the ball-bearings and stamped-steel of the slide. Nowadays, springs for self-closing and pistons for soft-closing are also being incorporated in the design. In the olden days, soft-closing pistons contained oil, but those had many disadvantages. Currently, these pistons are air-driven, which has drastically reduced the resistance offered by the drawers when you try to pull them out. But one needs to always keep in mind that drawer slides function in a slightly different manner when the drawers are filled. In case the cabinet design is of the soft-close under-mount type, then the drawer is constructed slightly wider and with a recess underneath to accommodate the slide and piston mechanism. For this a 1/8 inch clearance is given under the drawer. But if your drawer was originally constructed for side-mount slides, then you shouldn’t attempt to retrofit slides underneath it. Drawers that are side-mount type have four pieces while the under-mount type has five. This is because the front of the drawer is separately fitted to the box once the slide is in place. Nowadays, kitchen cabinet manufacturers have started incorporating the soft-close feature with the side-mount slide. But if you are a DIYer, then it is better to go for epoxy-coated slides as they are easier to put together without expertise. Door and Hinges Cabinet doors can have many different kinds of hinges – knife, exposed barrel, and European cup. Knife hinges are called that because a small part of the hinge sticks out like a knife. A spring mechanism can make this a self-closing system. Exposed barrel hinges, on the other hand, have their entire spine visible externally, and need a magnetic catch to allow the door to swing freely. European cup hinges are built inside the door with an internal spring for self-closing. If the cabinet contains a soft-closing feature, then it also contains an additional piston in the hinge mechanism. A blocking element is then needed to determine the position of the piston and the softening effect on the swing. Since cup hinges are built inside the side of the door, the soft-closing system may either be built-in or snap-on. Soft-close slides, hinges and doors are perfect for homes that don’t want neighbors to complain of banging door and drawers, and prefer peace and quiet. On wood cabinets the finish is just as important as how well the cabinets are constructed. The finish not only provides aesthetic appeal but is a key component in the protection of the underlying wood surface. It needs that protection from the moisture and chemicals that are typical in a kitchen.

(Keep in mind we're talking about wood cabinets here. Cabinets covered in laminate or melamine aren't coated with these types of finishes and surface treatments.) The amount of material to explain the science behind the varnishes, lacquers and other cabinet surface treatments could fill a book but it's not necessary for a basic understanding of how a cabinet is put together. What we'll focus on here are some of the common finishes that you're apt to encounter in your cabinet research and their important features. Materials These are the most common finish treatments that you'll find on kitchen cabinets:

The Finishing Process The cabinet finishing process is dependent on the type of finishes used and the individual cabinet maker's capabilities and formula. Large cabinet manufacturers may have sophisticated facilities and processes to apply the finish whereas smaller cabinet makers may take a simpler approach or even farm out the finishing process to a local firm that specializes in that type of work. Wood cabinet finishing involves a number of steps that involve preparing the wood, applying the surface treatments and baking the finish. For an example of one large cabinet manufacturer's method, check out the Cabinetry Factory finishing process of cabinet door. It's an example of the multiple steps that are taken in the cabinet finishing process. Larger cabinet makers may have the resources and advanced production capabilities to produce consistent quality finishes. Smaller shops may not have the same capabilities. One of the things on your checklist when researching smaller cabinet shops should be their finishing process. Achieving a quality finish requires controlled conditions free from airborne dirt and dust. Some finishes require baking to cure. That's not to say that high-tech production facilities are the only way to achieve a quality finish. Just be sure you understand your cabinet maker's finishing capabilities and whether they'll produce a product that will hold up to the rigors of the kitchen environment. One final point to remember is that the finish options you choose have a bearing on the final cost of your cabinets. Finishes that include hand-rubbed treatments or multi-step coating applications take time and ultimately raise the cost of the cabinets. Glazing can produce some nice effects but it's an additional step in the process. Ask yourself whether it's absolutely essential in your kitchen style. Otherwise you may be able to save some money on simpler finish treatments. Kitchen cabinets are the centerpiece of every kitchen design. They dominate the space and define your kitchen style with a combination of material, shape, color, and finish. Cabinetry is a practical component of the kitchen, containing essential storage space for all your kitchen tools, food, and more. The exterior of your cabinets is where your style is defined, based on your chosen door style as well as the finish. In this blog we will explore the array of cabinet doors available to help define your kitchen design style. Recessed PanelIn the simplest terms, a recessed panel cabinet is any door with a frame surrounding a central panel set back from the frame. You will sometimes see these cabinet doors referred to as “flat panel” (though just to make things confusing, flat panel and slab are sometimes used interchangeably). This cabinet style is generally simple, though you can find recessed panels with more intricate details like a beaded frame. Or make your recessed panel beadboard to achieve a more rustic, country style kitchen design. Recessed panel cabinetry works very well with both natural wood and painted wood finishes. ShakerShaker cabinetry is very popular, particularly with the growing trend toward transitional style kitchen design. The understated elegance of this cabinet style is ideal for transitional kitchens, but can also fit in a more contemporary, modern, or Scandinavian style design. Shaker cabinetry originates from the 1800s when the Shaker community produced simple, but high-quality furniture. Shaker is essentially a variant of recessed or flat panel cabinetry, with a minimalist style, meaning it has a basic frame with no extra decorative features. SlabSlab cabinetry is the most modern, sleek design available, with a completely flat door. It is sometimes referred to as “flat” or even “flat panel” cabinetry. Slab cabinetry is low maintenance as there are no edges or crevices to keep clean. For the most minimal, modern look this type of kitchen cabinet door can be installed with no handle. It can be found in everything from natural wood to glossy, quirky colors. Raised PanelLike recessed panel cabinets, raised panel has a frame consisting of four pieces of wood that surround a central panel. In this case, though, the central panel is raised with a profile or contour. This kitchen cabinet style is more typical in traditional kitchen designs, but you could find it suits a transitional style kitchen remodel as well depending on how ornate a central raised panel you choose. There is more customization of the design when it comes to raised panel as you can select different shapes for the panel. Glass FrontGlass front cabinets effectively replace the flat panel inside the frame of your cabinet door with a glass central panel. They suit almost any style kitchen design and serve to break up wooden cabinetry and enhance the brightness of your kitchen. Be aware that while they contribute to an open, airy feel in your kitchen they also expose the contents of your kitchen cabinets. Many people limit glass front cabinetry to only some areas (like upper cabinets), where they can carefully arrange glassware or more decorative items. Or choose frosted glass that gives a similar effect but helps to hide items inside the cabinet. If you want to go for a more decorative look, choose a mullion style door where the glass panels are broken up by strips of wood.

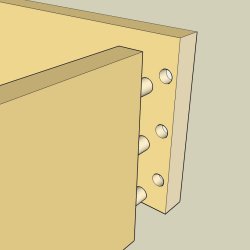

Cabinet Boxes & Face FramesMaterials Cabinet boxes are made from particle board, MDF or plywood. Solid wood panels normally aren't used to construct the cabinet box except for the face-frame on framed cabinets. Panels made from these wood products are usually covered in either a wood veneer, plastic laminate/melamine or thermofoil. Stainless steel is another material used to make cabinets though it's much less prevalent than wood. Stainless steel cabinetry provides a novel look and depending on the setting, resembles professional kitchens. On the plus side steel won't expand and contract like wood will in a kitchen environment. One of the down sides is the challenge in keeping the cabinets free from fingerprints which can be tough to clean. Construction The cabinet box is essentially just that - a box. The key point to understand here is that there are several methods used to reinforce the box and make sure it remains rigid. One means of reinforcing the cabinet box involves the use of triangular braces in the corners of the box. They're made from either particle board, MDF, plywood, solid wood or plastic. Another reinforcing feature uses an "beam" brace that runs from the front of the box to the rear on the inside of the side panels or along the back from side to side. The beam brace usually fits in a dado slot in the side panel. DrawersMaterials Cabinet drawers are predominantly made from the same materials that are used to construct the cabinet cases such as particle board, MDF, plywood and solid wood. On higher quality drawers more of the drawer parts tend to be made of solid wood to stand up the abuse from more frequent opening and closing. On stainless steel cabinets the drawers are made from stainless steel. Some cabinet manufacturers offer options for metal drawers on their wood cabinet lines. These drawers are coated with an epoxy coating. Drawer fronts, the part of the drawer that you see, tend to be made from solid wood or MDF that's either painted or covered with thermofoil. Construction The way a drawer is built plays a large role in its durability and longevity. The drawer box is made up of two side panels, front and back panels and the bottom. Most cabinet drawers have a separate front piece that's attached to the front drawer-box panel although on some drawers the drawer front and front panel are the same piece. The parts that make up the drawer box can be assembled in several ways. Dovetail joints that are tight form the strongest connection at the corners of the drawer. Doweled joints where one side of the drawer box has dowels installed on one end that fit in holes in the mating panel end is another form of joinery. Drawer bottoms that fit into dado slots in the drawer slides are stronger than bottoms that are just nailed and/or glued to the bottom of the drawer box. Glue, small nails and staples are also used to fasten drawer parts together. DoorsMaterials Cabinet doors, except for stainless steel cabinets, are made from solid wood or one of the engineered wood products (particle board, MDF, plywood). Engineered wood doors are covered with a wood veneer, laminate or thermofoil. One of the benefits of MDF is that it can be routed and cut, similar to solid wood, with better results than particle board which is less dense and tends to chip. This feature allows MDF to be formed with a smooth finish to resemble raised-panel doors. The only drawback however is that unlike solid wood, MDF can't be stained (it has no grain) so it has to be painted or covered in thermofoil. Construction There are two basic types of cabinet door construction - framed and slab. Framed doors are made up of an outer frame that is built around a panel in the center of the door. The edges of the panel fit into slots milled into the inside edges of the frame and are allowed to "float" within the frame to allow for normal expansion and contraction of the wood. Raised panel doors are a common variety of the frame door style. Slab doors don't have the separate parts like a framed door and are usually one-piece construction or the combination of several solid pieces of wood glued and joined together to form a solid slab. Slab doors made from plywood or MDF are covered in a veneer, laminate or thermofoil covering. ShelvesMaterials

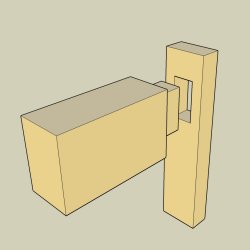

Cabinet shelves are made from one of the engineered wood products - either plywood, MDF or particle board. Regardless of which material is used they're normally covered with another material such as a wood veneer or laminate ply. Construction There really isn't much to a cabinet shelf's construction except for the mention of thickness and whether it's built with a reinforcing rail. Beyond that we're just talking about straight boards made out of one of the materials mentioned above. Shelf thickness varies based on cabinet manufacturer and the particular product line (often equating to the level of quality) within a certain brand. Shelf thickness ranges from 1/2" to 5/8" to 3/4" thick. Obviously thicker is better when it comes to longer shelves on wide cabinets in order to avoid sag. The reinforcing rail is an additional strip of wood that's attached to the front edge of a shelf. It provides added rigidity which is especially helpful in avoiding sag, particularly on long shelves. It's a worthwhile feature if you can find it but it's not a prevalent feature on many manufactured cabinets. One additional aspect about cabinet shelf construction lies not so much with the shelf itself but how it's held in the cabinet box and whether or not it's adjustable. Shelves are held in place with a variety of hardware that come in different sizes and materials (metal or plastic). Kitchen cabinet construction isn't rocket science nor do you need to know every last detail about it. But even if you're not the type of person who's inclined to ponder "how things are put together", it's still helpul to understand the basic parts and how they're constructed. That way you'll have a better feel for the different levels of cabinet quality and what you do or don't get for the various levels of cost you'll encounter. Cabinet MaterialsMost of us think of kitchen cabinets as being made out of wood and that's true for the most part. But don't think that it's all "solid wood" like the lumber used to frame a house. There are other materials that go into the construction of cabinets. Some are wood-based but others are not. Here's a list of the primary cabinet materials you'll encounter: Solid wood - just as the term implies, it's solid homogeneous wood, all the way through. The only variation might be boards or panels that are several pieces of solid wood joined together. Particle board - an engineered wood product that's made from wood chips and particles that are combined with an adhesive and fused together into boards and panels. Particle board makes up a large percentage of the materials used in today's cabinetry, from the panels that make up the boxes to shelving. Medium density fiberboard (MDF) - another engineered wood product that's made up of wood fibers. The fibers are combined with an adhesive under pressure and formed into boards and panels. MDF has a finer texture than particle board and is denser and heavier than particle board. It's used in cabinet doors, shelves and cabinet boxes. Plywood - yet another engineered wood product but one that's probably most familiar to people. It's made up of thin wood "plies" or layers of wood that are glued together in a sandwich form. Usually the plies are oriented with their grain direction at varying angles with respect to each other to give the board or panel more rigidity and stability. Plywood is used for shelving, doors and cabinet boxes. You'll typically see plywood as an upgrade (and corresponding up-charge) from particle board or MDF from many cabinet makers. Or sometimes the plywood cabinet boxes are only in the manufacturer's higher-end product lines. Also, be watchful for the terms "solid wood" or "all wood" in a manufacturer's description or literature. "Solid wood" should represent whole, uniform lumber, not a fabrication or wood composite, like particle board, MDF or even plywood. "All wood" is slightly different in that it usually means all-plywood construction or a combination of plywood and solid wood. The point is, just be sure when you encounter these terms that you're clear on whether it's truly "solid wood" or plywood so you don't run into any surprises. Stainless steel/metal - Stainless steel is used to make complete cabinets though it's much less prevalent than wood cabinetry. There are whole cabinets (boxes and doors/drawers) made from stainless steel and there's also some manufacturers that produce stainless steel doors for wood cabinets. Plastic laminate - this is virtually the same material that's used on laminate countertops although it's usually thinner when used on cabinets. It's basically a plastic product, formed by fusing paper and plastic resin together under heat and pressure. Laminate's used for covering cabinet boxes and/or doors to provide a easily-cleaned surface. Melamine - another plastic-based product that's also used to cover cabinet surfaces. It's a popular material for covering particle board panels that are used in making cabinet boxes. One type of construction you may see involves cabinet boxes made with melamine and wood veneer over particle board. The melamine is on the inside part of the cabinet and the wood veneer is on the outside of the cabinet box. Thermofoil - a thin vinyl film that's used to cover cabinet boxes, doors and drawer fronts. The vinyl usually starts as a rigid film that's then heated and formed over the substrate material (such as cabinet door made from MDF). You'll usually encounter the term "thermofoil cabinets" which implies cabinets that are covered with the thermofoil material (the base material will usually be one of the engineered wood products). Kitchen Cabinet Construction MethodsMethods for building and assembling cabinets will vary based on manufacturer and the level of quality you pay for. There's no need to become a master carpenter to be an informed cabinet buyer but there are some terms and construction techniques that you'll probably encounter, even if it's just browsing a cabinet maker's brochure or website. The important thing to take home on this subject is that there is a relationship between the type of construction and the cabinet's level of quality and durability. The following terms describe some common methods of wood cabinet "joinery" ('joinery' just being the trade term for how the various wood parts are joined together):

Nails, screws, staples, glue - while these aren't classified as true wood 'joinery' techniques, they're included because they're also used in a lot of cabinet assemblies. They either reinforce the wood joinery techniques or they're used alone which makes for less-sturdy construction.

The bottom line on cabinet construction methods is that good joinery techniques where the parts 'lock' together or where one piece is captured in the other makes for the strongest joints. Supplemental fastening methods on these joints (such as a mortise and tenon joint plus screws) makes an even stronger connection. Stronger joints equate to more durable cabinets. |

Kitchen Cabinets Factory in Vietnam

Archives

May 2024

Categories

All

|

Copyright© Cabinetry Factory All Rights Reserved

RSS Feed

RSS Feed